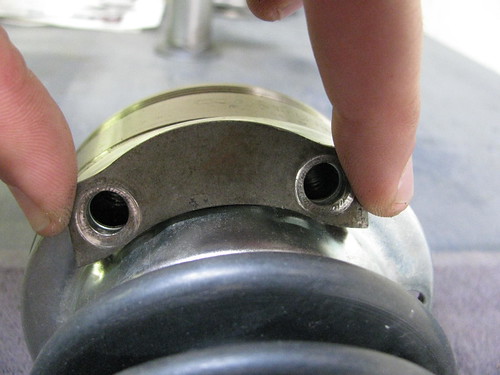

I have four new CV joints and new heat exchangers.

The gas tank is refurbished, released, has a new fuel gauge sender, and a repainted firewall.

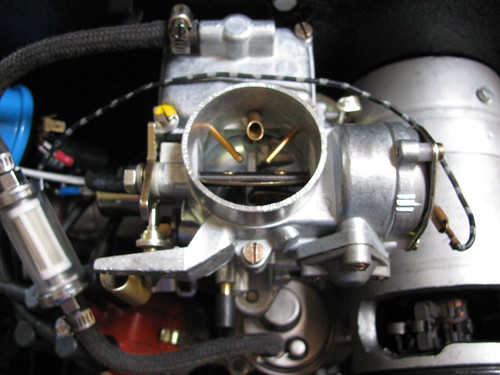

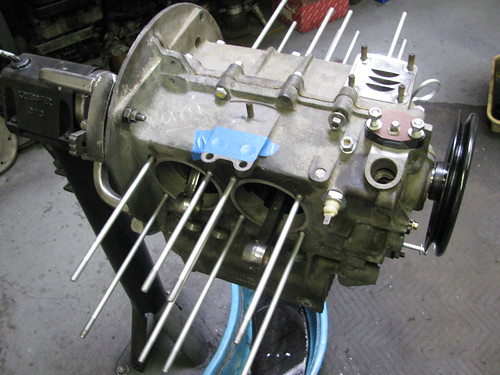

This is the engine rebuilder doing a final carb adjustment.

Several Thanks are due here.

First to John Marignac who not only sourced his finest people and parts, but took the time to make sure that everything would be as if it was his car. He has been picky and meticulous, and when I helped out, checked my work for perfection.

My Wife - who let's me have a vehicle for a mistress. Love you honey. I really do.

VW Camper Family - who has been patient with me while I work on it and miss campouts.

My random friends who have given me rides to places to pick up parts while the vehicle was in the shop.

Next stops. A valve adjustment at 200, 500, and 1000 miles. Then a road trip.

-Peter